Crane Tracks

30 January 2025

Cranes (and therefore crane tracks) can play a major role in business operations. It is therefore important that you can rely on the flawless operation of the faucets. On this page you can find all information regarding crane tracks.

- What are crane tracks exactly?

- What types of crane tracks are there?

- What is an overhead crane?

- How does an overhead crane work exactly?

- How much does a gantry crane cost?

- What types of overhead cranes are there?

- What are HB Systems?

- What types of HB Systems are there?

- What is a crane track profile exactly?

- Inspection and maintenance of crane tracks is of great importance

- Installing or repairing crane tracks? Our specialists are ready to assist

What are crane tracks exactly?

The foundation of a crane is the track on which the crane moves. This is also referred to as a crane track, and in plural, crane tracks. It is of utmost importance that crane tracks are well-maintained.

This is because the frequent load variations on the crane track can potentially lead to damage to the crane rails, the crane track, and eventually the crane itself.

Construction of crane tracks by the experts of Kraan & Baan Techniek

What types of crane tracks are there?

There are many different types of crane tracks. In every factory or organization where something is produced, solutions for material flows and related logistical challenges need to be considered.

Anyone who thinks that only large industrial companies need cranes and crane tracks is mistaken. There are thousands of smaller craft businesses that also seek logistical solutions for their material flows. Additionally, there are organizations that face special requirements for transportation. This could be related to the company’s location or the type of material that needs to be transported.

Kraan en Baan Techniek provides every type of crane track for all types of cranes. The most popular types of cranes are overhead cranes and HB systems. Below, we elaborate on these types.

What is an overhead crane?

An overhead crane is the ideal solution for moving extremely heavy goods within an indoor workspace. Overhead cranes can easily cover large spans as well. A crane track is also referred to as a bridge crane.

An example of an overhead crane. Kraan & Baan Techniek supplies the crane tracks for this

How does an overhead crane work exactly?

An overhead crane travels along the top of a workshop and consists of a crane girder equipped with runway beams on both sides. In the case of a double girder overhead crane, the hoist travels on a frame above the girders, and for a single girder overhead crane, the hoist hangs from the flanges beneath the girder.

To operate an overhead crane, you need a lifting permit and a certificate is necessary.

How much does a gantry crane cost?

A question we often receive is “how much does a gantry crane cost?” Since there are many different types of gantry cranes and it’s often customized with various gantry crane components, it’s difficult to provide an exact cost for a gantry crane. In the section below, we will guide you through the most commonly sold gantry cranes.

How much does a gantry crane cost?

A question we often receive is “how much does a gantry crane cost?” Since there are many different types of gantry cranes and it’s often customized with various gantry crane components, it’s difficult to provide an exact cost for a gantry crane. In the section below, we will guide you through the most commonly sold gantry cranes.

What types of overhead cranes are there?

In addition to a single girder overhead crane and a double girder overhead crane, there are also a suspended overhead crane and a wall-traveling crane. Below, we briefly explain each of them. Kraan & Baan Techniek can arrange the crane tracks for any type of overhead crane.

Single Girder Overhead Crane

The single girder overhead crane is one of the most versatile, efficient, and cost-effective types to use. It features only one single girder that travels along the rails. It can easily move heavy loads ranging from 5 to 100 tons.

Double Girder Overhead Crane

In a double girder overhead crane, there is support from the runway beams on both sides. The lifting device is positioned between them. The significant advantage of this setup is that the load is better distributed, resulting in less strain on the building structure. An additional benefit is that larger suspension distances become feasible as a result.

Suspended Overhead Crane

A suspended overhead crane (suspended crane) is attached to the ceiling of the workshop. A major advantage of suspended cranes is that they don’t require crane runway columns. This allows you to utilize the workspace much more effectively. Suspended cranes are used for spans up to 30 meters and loads of up to 16 tons.

Wall-Traveling Crane

Wall-traveling cranes are also referred to as console cranes. They move on a separate level (plane) below the main overhead cranes and are a perfect solution for assisting multiple workstations simultaneously.

An example of a wall-traveling crane

What are HB Systems?

The HB System is also known as one of the most successful discoveries in the field of lifting and transportation technology. It combines the capabilities of a stationary hoisting device with the mobility of an overhead crane.

What types of HB Systems are there?

There are many different types of HB Systems. Below, we have provided an overview of the most popular HB Systems.

Monorail Track

A monorail track is designed for on-site lifting and linear transportation from one point to another. By utilizing special curve sections, the lifting device can be moved throughout the entire hall as needed. This allows, for example, workstations to be connected or machines to be relocated.

An example of a monorail track

Double Rail Track

In a double rail track, two crane tracks are suspended parallel to each other. The lifting device is positioned between them. The significant advantage of this setup is that the load is better distributed, resulting in less strain on the building structure. An additional benefit is that larger suspension distances become feasible as a result.

[caption id="attachment_423" align="alignnone" width="453"]

Single Girder Monorail EHB

The single girder monorail EHB is a ‘lightweight solution’ for the complete transport of materials within industrial premises. The lightweight nature of this monorail lies in its simple construction with a crane girder and two rails. This makes it easy and trouble-free to move manually. The single girder crane is perfectly suitable for installation in industrial halls with a lightweight structure and lower load capacity.

Example of a single-girder monorail EHB

Single Girder Monorail EHB-X

The single girder monorail EHB-X is the solution when the headroom of the single girder monorail EHB is insufficient. In this monorail, the crane girder hangs between the crane tracks instead of beneath them.

This means that the entire crane has only the height of a single profile. This significantly increases the lifting height. Thus, materials that need to be moved can be hoisted over tall machines, for example.

Double Girder Monorail ZHB

The double girder monorail ZHB allows for extremely long crane girders, which can cover an entire industrial hall. The monorail features a double girder that hangs below three crane tracks. Nothing is impossible with this unique gantry crane.

Double Girder Monorail ZHB-X

The double girder monorail ZHB-X is a monorail with a double girder where the crane girders are located between the crane tracks (rather than beneath them). When the headroom of the double girder monorail ZHB is insufficient, this monorail is often used. In this case as well, the X version significantly increases the lifting height.

Double Girder Monorail ZHB-3

This type of monorail showcases a tremendous range of possibilities. The double girder monorail ZHB-3 hangs below three crane tracks. This allows for covering an entire industrial hall using extremely long crane girders.

Single Girder Monorail EHB-I

The single girder EHB-I is a well-thought-out solution for comprehensive material transport in factories or industrial halls when the rail size is not larger than what can be spanned with the EHB profile. This lightweight crane girder has a hollow profile and can be moved directly on this crane track made of rolled profiles, connected with the two under-hung trolleys.

Double Girder Monorail ZHB-I

The double girder monorail ZHB-I is a perfect solution for comprehensive transportation of heavy loads. This type excels due to its long crane girders. The crane moves effortlessly on a gantry crane made of rolled profiles. Additionally, it features a high hook position.

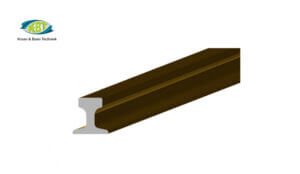

What is a crane track profile exactly?

A crane track profile refers to the type of crane track. Choosing the correct type of crane track is crucial for the longevity and safety of the crane track.

Different crane track profiles are suitable for various applications. This choice depends on factors such as the load capacity, intensity, and speed of the crane track. Another term for crane track profile is rail profile.

Inspection and Maintenance of Crane Tracks is of Great Importance

A well-maintained crane track is crucial for ensuring the safety of operations within an organization. Regular inspections can identify issues in a timely manner, preventing potential failures due to a poorly functioning crane track.

Kraan en Baan Techniek specializes in crane track inspection. We thoroughly inspect the crane track and conduct on-site measurements. After the inspection, you’ll receive a report containing our findings and recommendations to keep the crane track in the best condition.

Installing or Repairing Crane Tracks? Our Specialists Are Ready to Assist

In addition to installing new crane tracks, we also carry out repairs. Following the repair, you’ll receive a final report with accurate measurement data to demonstrate that the repaired crane track is within tolerance. This provides assurance for the crane’s proper operation and minimal wear of the crane tracks in the future.